Bottom Slitter

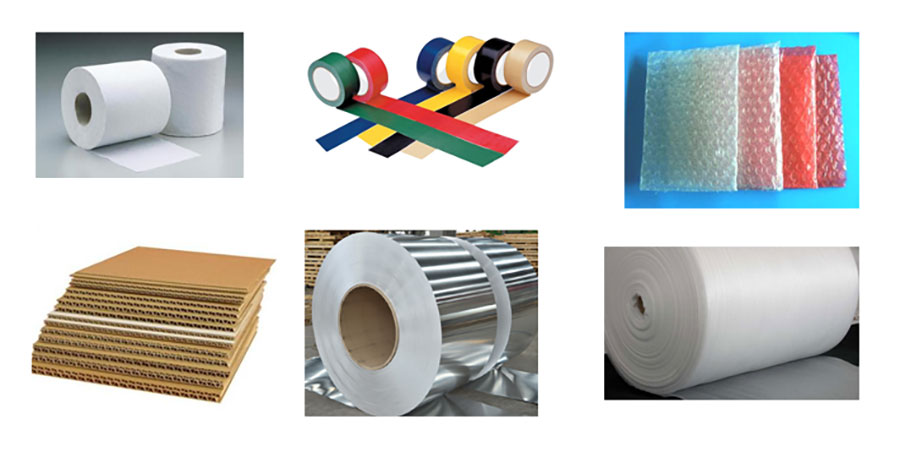

Multi-blade slitting equipment are the ideal slitters for companies converting a variety of materials, in sheets, plates or rolls including; heavy rubber, conveyor belting materials, foams & laminated foams, non-asbestos, cork, non-wovens & textiles, polyethylene, polyurethane, plastic films, fiberglass, graphite, foam tapes & reinforced tapes, roofing products and similar materials.

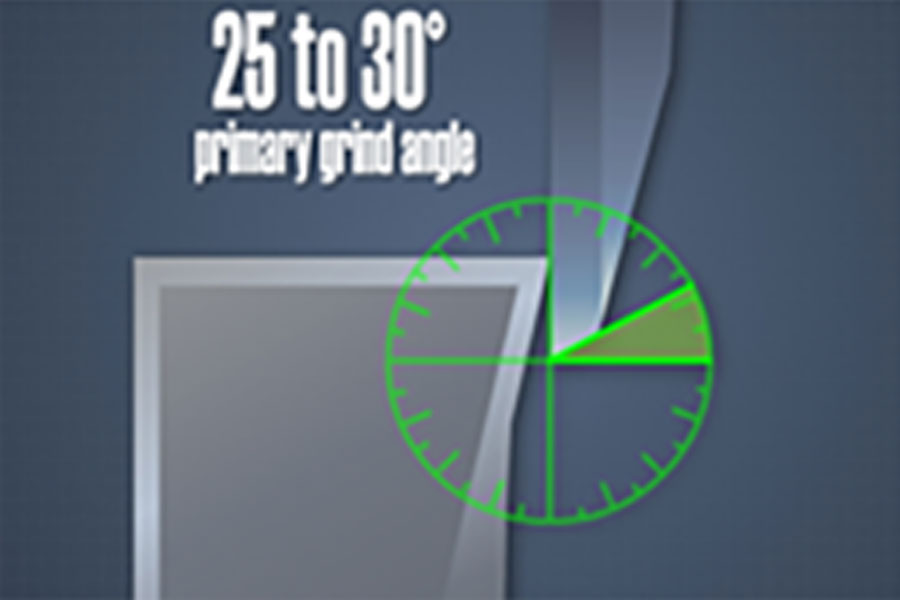

The slitter system of a winder typically includes multiple sheet guiding and support roles, the slitters themselves, the spreader rolls before and after the slitters. The slitters cut the sheet into the desired roll widths, and also trim off the front and back edges. Depending on the requirement, the number of slitters can vary from 3 to 20 or more. Slitting is typically accomplished by multiple pairs of rotating knives mounted on shafts or rails. The cuts or slits are made at the points where the top and bottom slitter knives make contact. On paper and board machine winders, the top slitters are typically circular blades and the bottom slitters are usually bands.

According to Various Cutting Materials, Different Materials would be chosen to produce the bottom slitter or base.

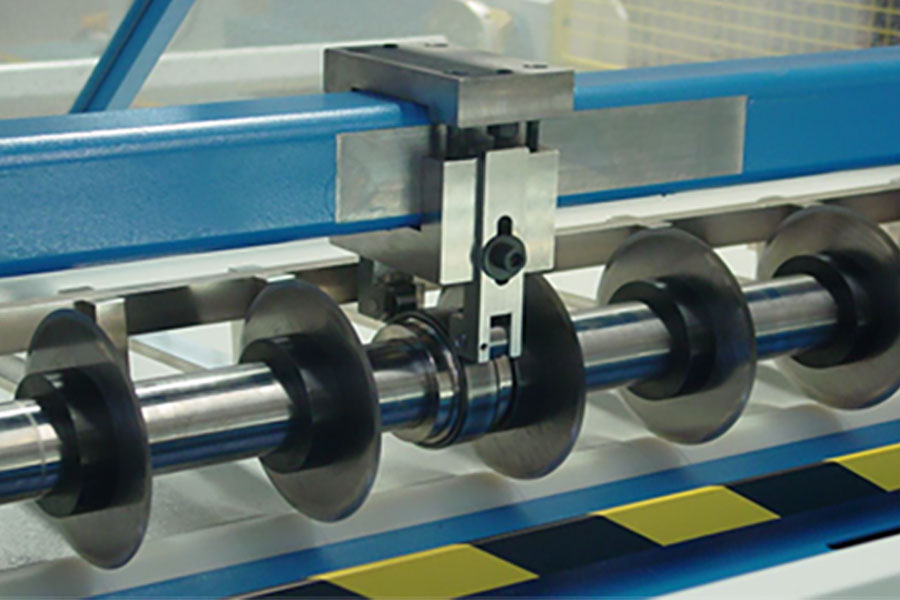

Slitting Machine

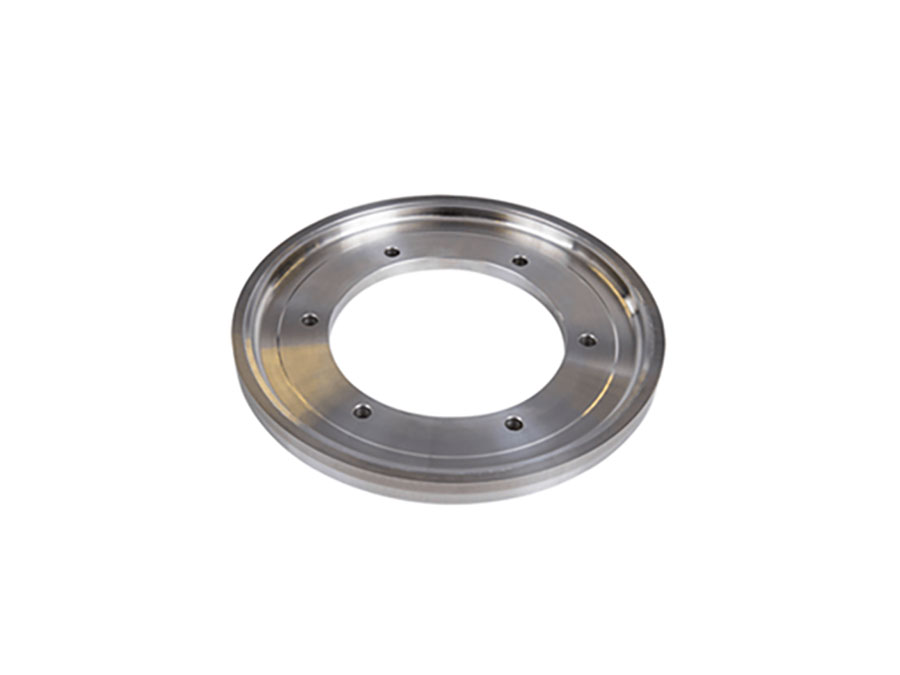

Bottom and Top Slitter;

Materials: Tungsten Carbide or Hardened Steel Carrier

Application of Top Slitter and Bottom Slitter

How to get the price of bottom slitter?

- a. Send us the profile of Bottom Slitter?

- b. Materials requirement

- c. application of Bottom Slitter?

联系我们

-

ShangCheng Cutting Co., Ltd

-

YanTa District, XiAn, ShannXi Province, China