Diamond Grinding Wheel

The structure of the diamond wheel is different from that of ordinary abrasive wheel, which is generally composed of diamond abrasive layer, transition layer, and matrix. The working layer, also known as a diamond layer, is composed of abrasive, binder and filler and is the working part of the grinding wheel. Transition layer, also known as a non-diamond layer, is composed of binder, metal powder, and filler.

It is the part that firmly connects the diamond layer to the matrix. The matrix is used to receive the abrasive layer, and when used, it is firmly clamped on the spindle of the grinding machine with flange plate.

Application of Diamond Grinding Wheel;

Due to the characteristics and advantages of diamond abrasive, the diamond grinding wheel has become the ideal tool of choice for grinding hard and brittle materials such as glass, ceramics, gemstones, stones and cemented carbide.

The metal-bonded diamond grinding wheel has high holding strength, long service life and little abrasion, which makes the diamond grinding wheel give full play to its advantages in high-speed and ultra-high-speed high-efficiency and high-precision grinding. The characteristics of strong abrasion resistance cutting ability, especially in the hard brittle hard material more obvious advantages, widely used. The diamond grinding wheel has been used in almost every field of industry, Aerospace, mold manufacturing, semiconductor manufacturing, optical processing manufacturing, etc. At present, ceramic materials, optical materials, aero-engine turbine blades, silicon wafer products and other multi-purpose.

Advantages of Diamond Grinding Wheel;

A diamond wheel is an ultra-hard abrasive wheel. Compared with an ordinary abrasive wheel, it has obvious features and advantages:

- High efficiency grinding and the grinding tool has the longest service life.

- high abrasion resistance, small abrasion of grinding wheel, high production efficiency and meet the requirements of high efficiency and precision machining tools.

- good cutting performance reduces grinding power and saves energy.

- good thermal conductivity, conducive to heat evacuation.

Types of Diamond Grinding Wheels:

The diamond grinding wheel can be divided into:

- Resin-bonded diamond grinding wheel;

- Ceramic bonded diamond grinding wheel;

- Metal bonded diamond wheel (bronze bonded diamond wheel)

- Electroplated diamond

Shape Types of Diamond Grinding Wheels:

According to the appearance or shape, the diamond grinding wheel can be divided into parallel grinding wheel; Cylindrical grinding wheel; Cup wheel; Bowl wheel; Disc wheel; Edge grinding wheel; Mill, etc.

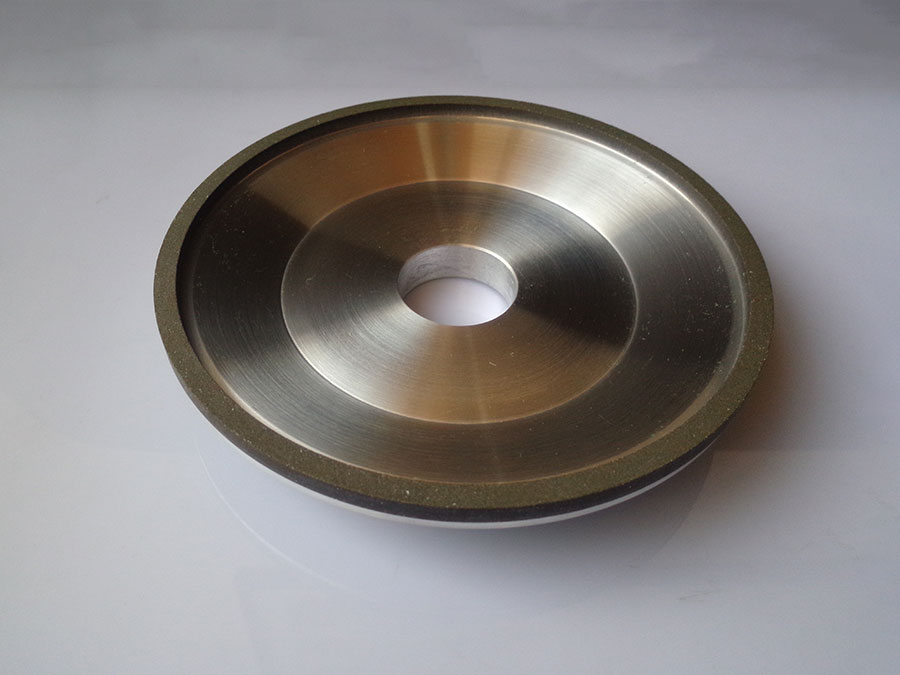

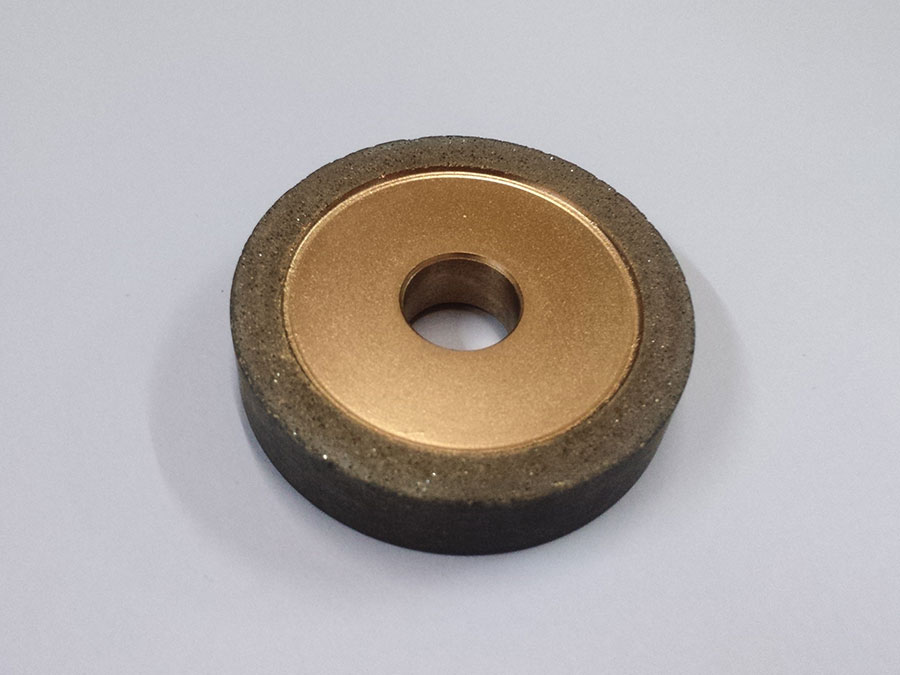

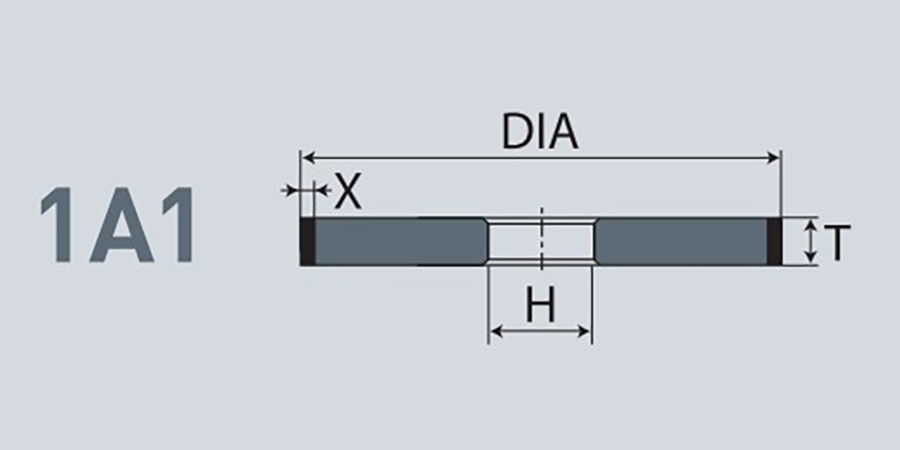

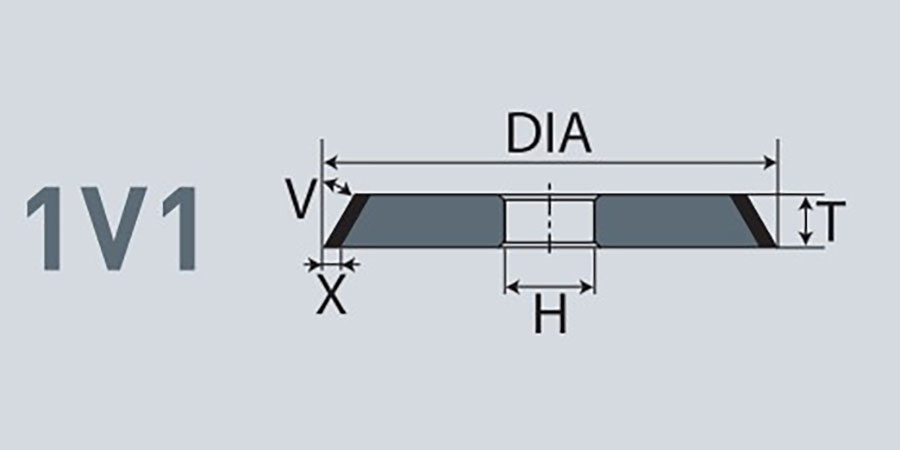

1A1 Diamond Grinding Wheel

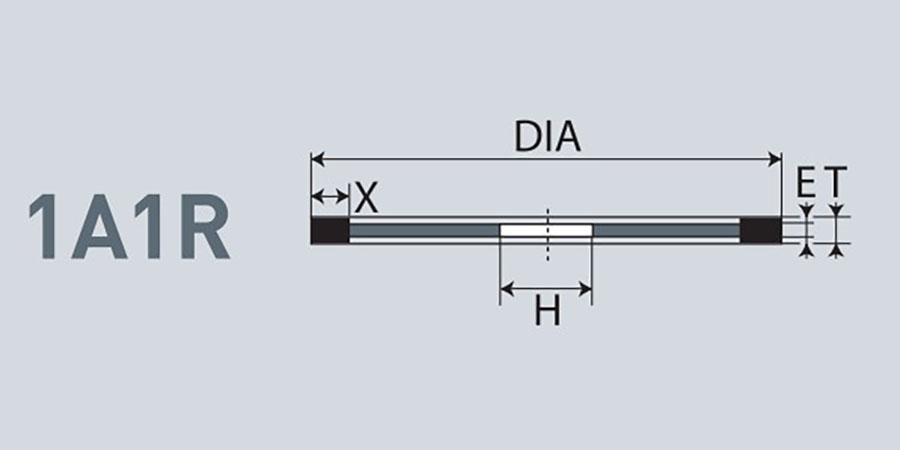

1A1 R Diamond Grinding Wheel

1A1 Diamond Wheel

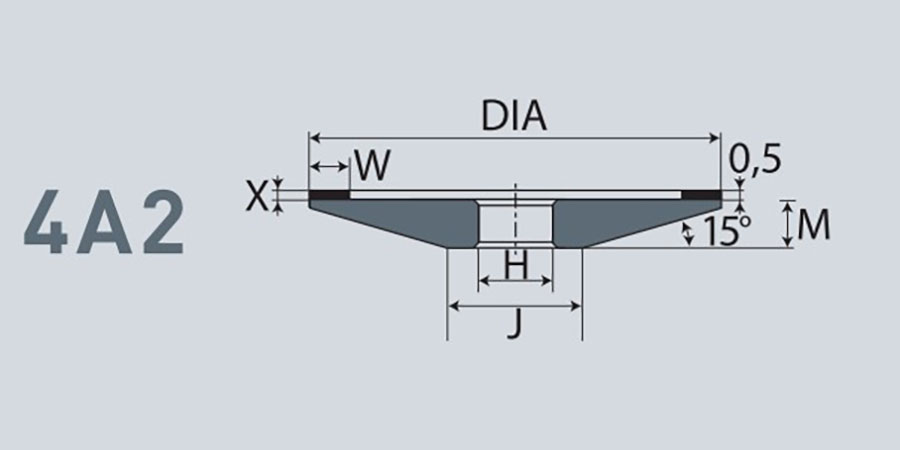

4A2 Diamond Grinding Wheel

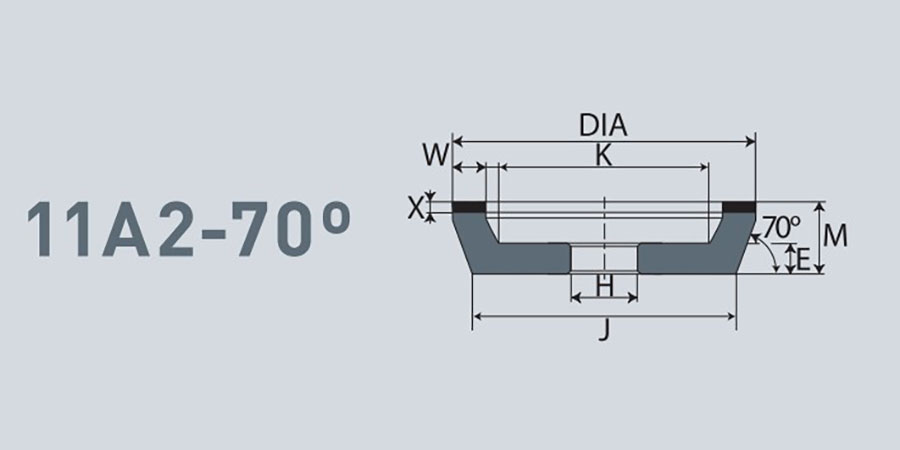

11A2 70 Diamond Grinding Wheel

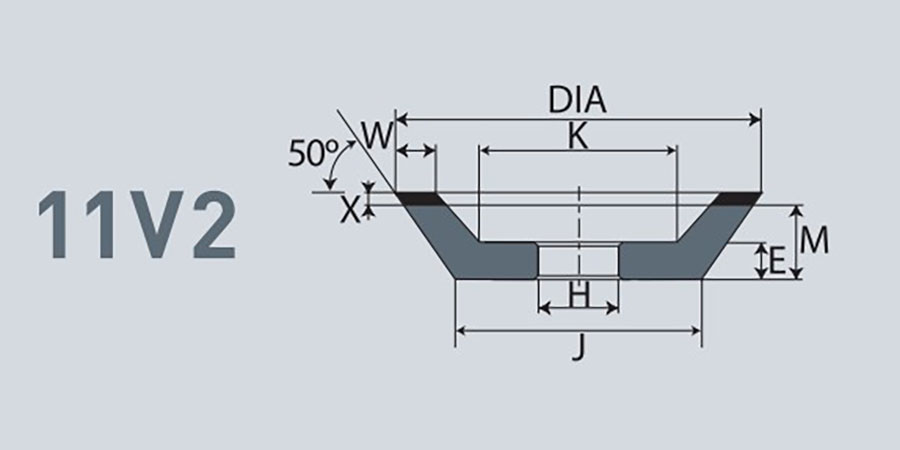

11V2 Diamond Grinding Wheel

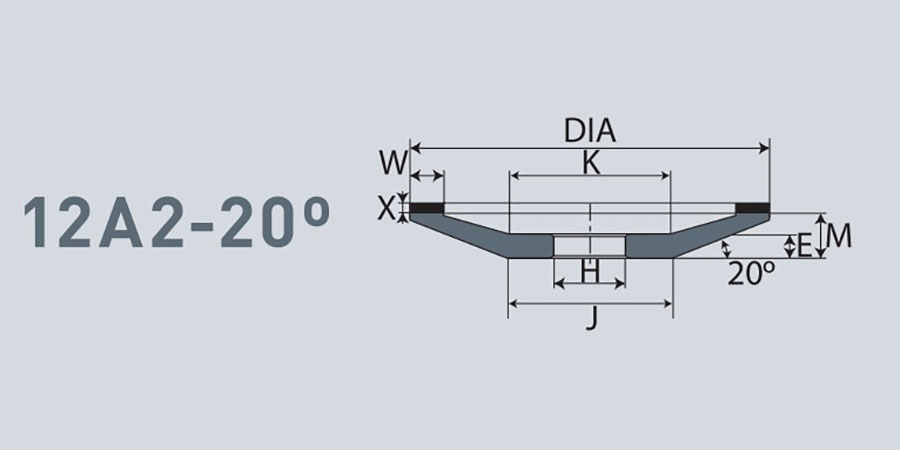

12A2 Diamond Grinding Wheel

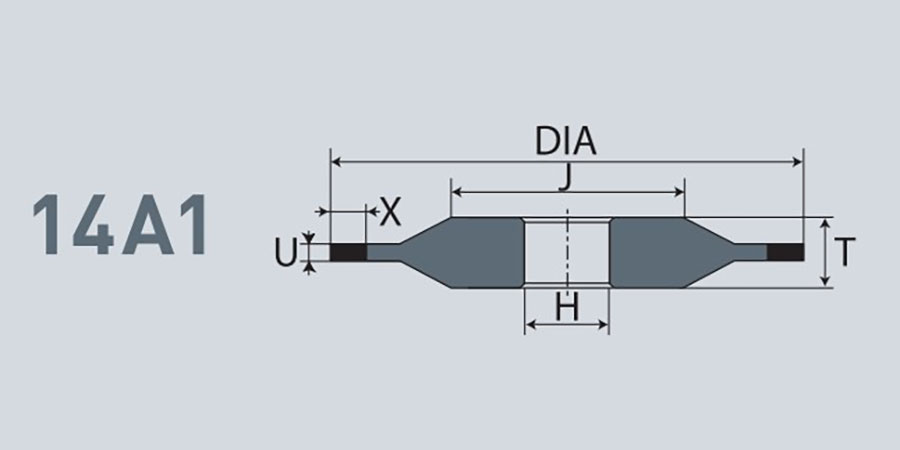

14A1 Diamond Grinding Wheel

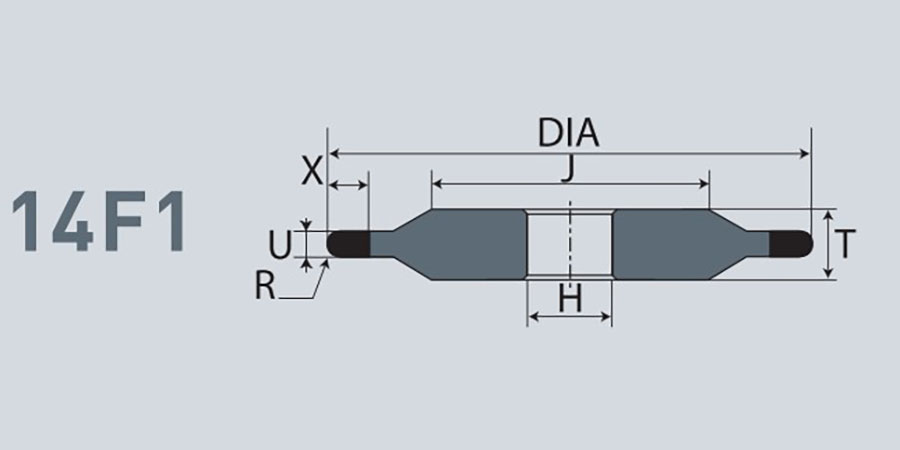

14F1 Diamond Grinding Wheel

Related Products

联系我们

-

ShangCheng Cutting Co., Ltd

-

YanTa District, XiAn, ShannXi Province, China